December 23, 2018

7-Story, 106,000+ Self-Storage Building

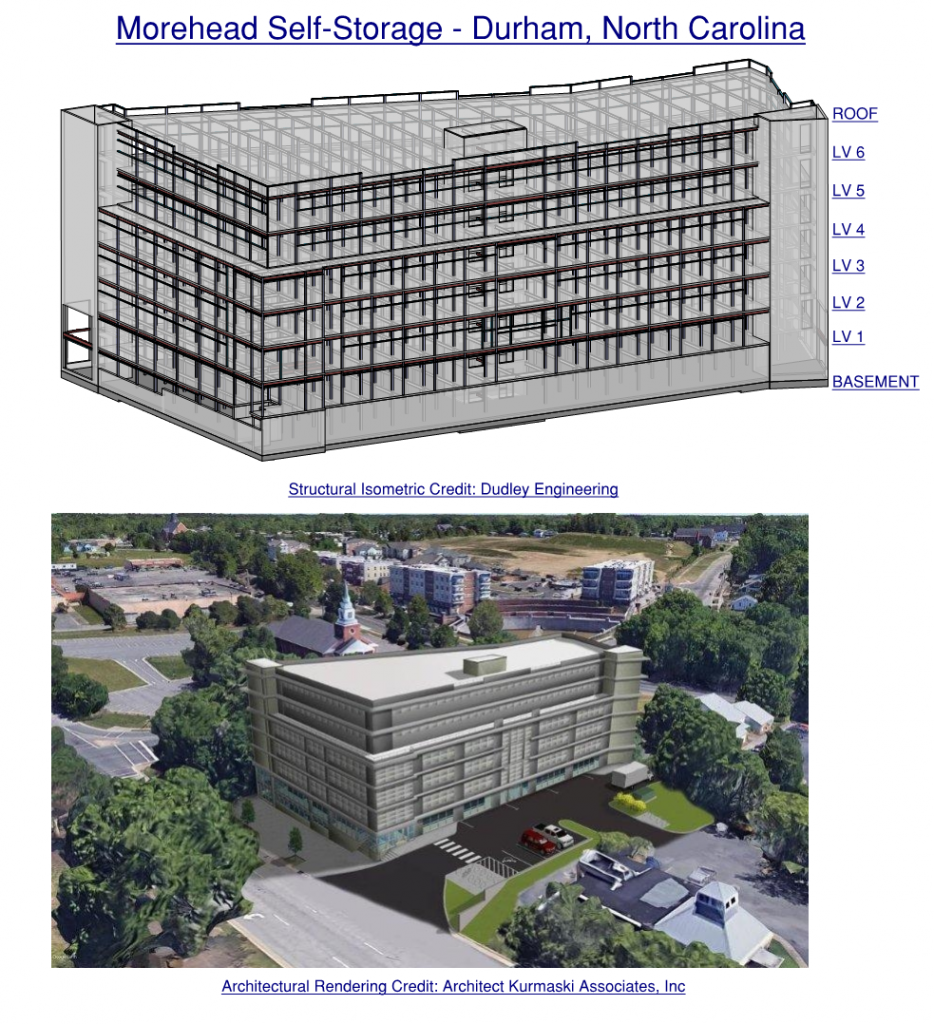

Dudley Engineering served as the engineer-of-record on this 7 story, 106,000+ self-storage building in Durham, North Carolina. The structural framing consists of the structural steel HSS posts with wide flange beams and composite deck. The lateral system consists of ordinary concrete shear walls which for which insulating concrete forms (ICF) were used for formwork.

The design/builder on this project was ARCO Design / Build and the architect was Architect Kurmaskie Associates, Inc.

Innovative Structural Framing

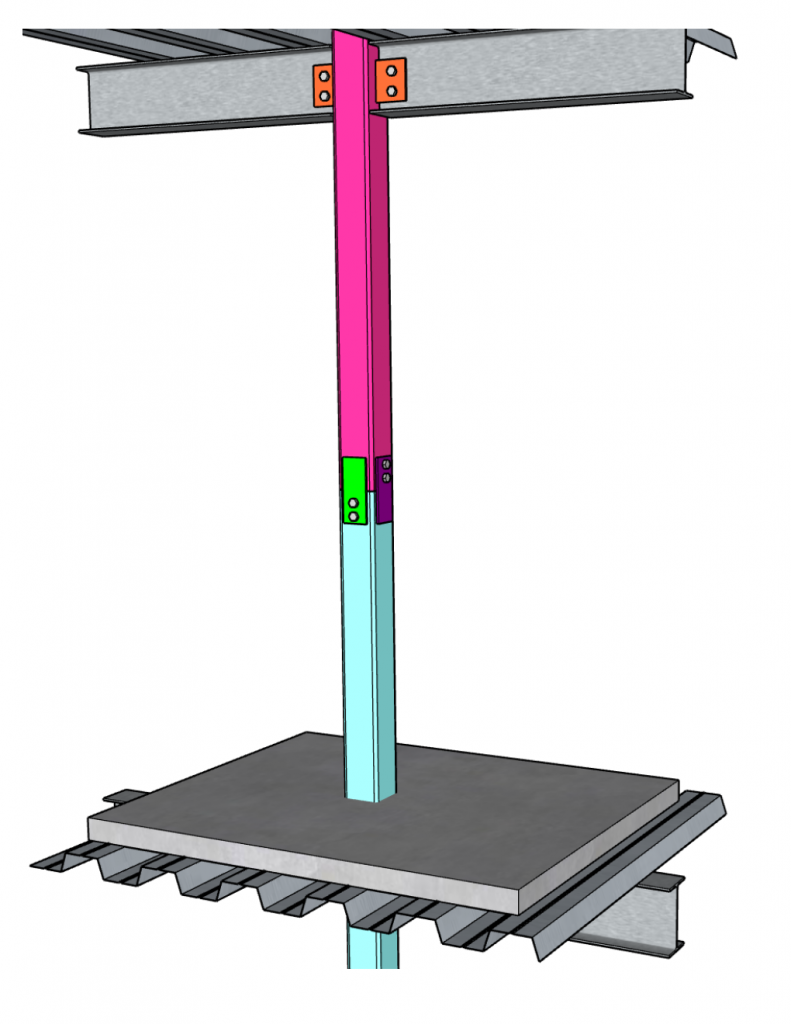

Efficient Column Splice Connection

Due to the modular layout of self-storage buildings, the structural column grid was able to essentially maintain a 10’x10′ grid. Dudley Engineering derived the connection detail below that occurs in between Level 3 and Level 4 for most columns. The benefits of this connection detail include the following:

- Connection eliminates the need for the field welding and instead only required bolts which greatly reduces erection time.

- Splicing between the 3rd and 4th level reduces the number of pieces (sticks) that the erector has to install while still keeping all members shorter than 60 feet to accommodate freight limits.

- Due to the sleek plates that hardly protrude outside the column, the splice connection does not interfere with the function of the storage unit.

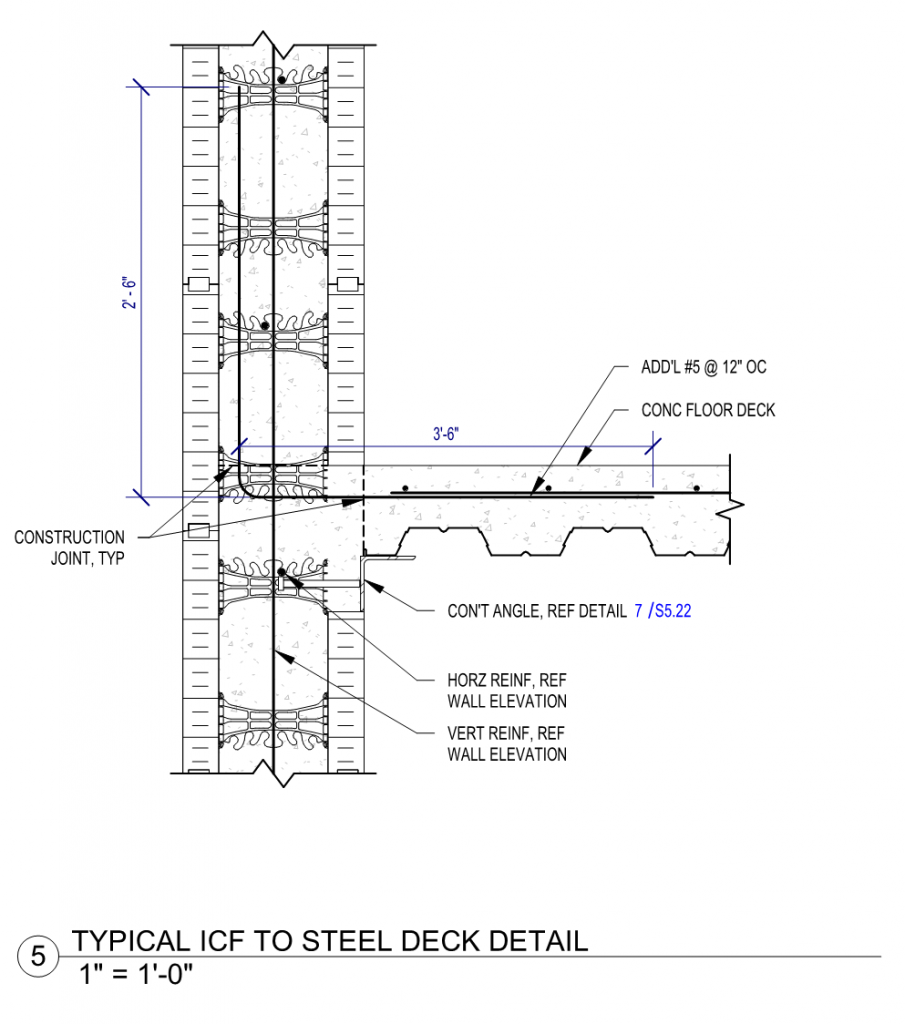

Insulating Concrete Forms (ICF) for 7-Story Concrete Shear Walls

Dudley Engineering developed a lateral load resisting framing plan that utilized the elevator and stair shafts to form ordinary concrete shear walls, the benefits for which inlcude:

- Floor plan is considerably more flexible to future adjustments since there will not be any diagonal strap braces or PBU metal deck shear walls that can’t be removed. In other words, everything except for the HSS columns is non-structural and be removed/replaced without any modifications.

- Save construction costs and erection time by removing steel diagonal strap bracing.

For the shaft walls alone to provide the necessary lateral capacity for the building to resist wind and seismic loads, they needed to be formed out of cast-in-place concrete in lieu of CMU. Additionally, in order for the concrete walls to be cost-effective the contractor (ARCO Design/Build) had to find an alternative to the traditional form work system which can be very expensive.

ARCO Design/Build proposed the use of Insulating Concrete Forms (ICF) which allow the wall formwork to be erected similar to a CMU wall however the final product is a cast-in-place concrete wall.